PACKAGING & CUSTOM BARCODING

VALUE-ADDED SERVICES

Standard Slit Packaging

Hardwood Runners 3” x 3-1/2’

* Used on all skids

Hardwood Top Boards 1” x 6”

* Used on all skids

Moisture Barrier Paper

* Placed between Top Board and Metal

Plastic Strapping ¾”

* Used for I.D to O.D. strapping in 3 locations 12 o’clock, 4 and 8

* Used to secure metal to wood skid

Metal Banding ¾”

* OD strapping around each slit cut .041 gauge material and over

* Strapping Tape on OD Tail Edge on .040 gauge material and under

Plastic Stretch Wrap

* Wrapped around entire skid after strapping metal to skid

Strapping Tape

* Used on OD Tail Edge on .040 gauge material and under

Cardboard Corners

* Used to protect corner of slit metal where strapping meets the metal when strapping metal to skid

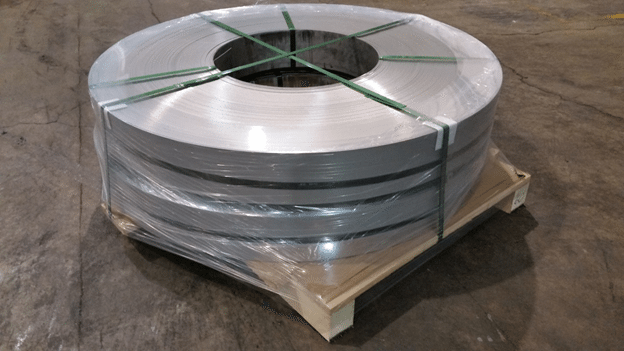

Standard Coil Packaging

Hardwood Runners 3” x 3-1/2”

* Used on all skids

Hardwood Bottom Boards 1” x 6’

* Used on all skids

Corrugated Cardboard

* Full coverage outer warp around OD of coil

Plastic Strapping ¾”

* Used to secure coil to wood skid

Metal Strapping ¾”

* OD strapping around coil average of 3 areas depending on width and gauge of material

Strapping Tape

* Used on OD of Tail Edge on .040 gauge material and under

Cardboard Corners

* Used to protect corner of metal where strapping meets the metal when strapping metal to skid

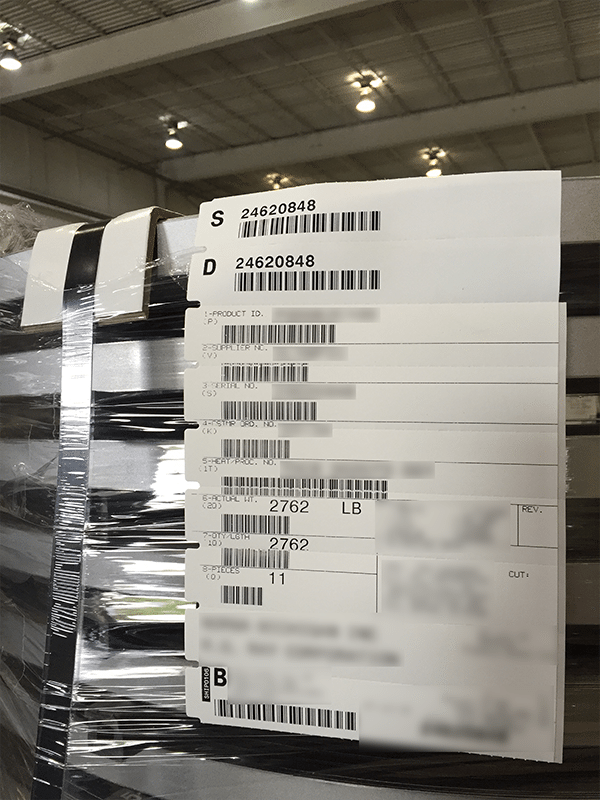

Custom Barcoding

Integrity Stainless offers custom barcoding/labeling specifications for easy and efficient data collection at your facility. It is our focus to provide customers with this beneficial solution to prevent any issues or delays of product processing.

Barcode Specifications

- Customized Fonts

- Customized Barcode Styling

- Customized Title Block Descriptions

- Customized Data Identifier Codes

- Barcode Symbol Formats

- Barcode Heights

- Narrow Element Limits

- Quiet Zones

VALUE-ADDED SERVICES

STAINLESS STEEL

All Rights Reserved | Integrity Stainless